Anvil is a component of a static pressure device which can create ultra high pressure and high temperature when working, this pressure is widely applied in the production process of hard materials synthetic diamond, Cubic Boron Nitride (CBN) etc... The anvil is installed on the top of the big pad of the piston of the six-side jacking machine. When driven by the oil cylinder, a group of six anvils is closed to form a high-pressure cavity. The pressure of the cavity body can reach 10-20gpa and the temperature above 1500℃, hence the anvil bears the supercritical compressive stress, tensile stress, shear stress and compressive strength. Therefore, the anvil is mostly made of WC-Co(tungsten carbide and cobalt), which has high strength, wear resistance and good toughness and thermal stability.

1. Anvils. We focus on the 6 facet anvils and 2 face anvils which are applied to the synthetic diamond and white diamond producing process, in the press machines.

Press machines which the carbide anvils applied in:

Anvil Carbide Grade Physical Characters:

| Grade | Physical characters | Remark | |||

| Density | Hardness(HRA) | TRS | Porosity | ||

| BDC8A | 14.8 | 90 | 3200 | A02B00C00 | All carbide anvils are pressed by a cold isostatic pressing machine and 6MPa HIP sintering. |

2. Anvil inserts. We produce the carbide anvil inserts for producing Synthetic Diamond as well, insert parts can be in a blank or fine finishing situation. A very precise arc of the carbide insert can be made by EDM at a competitive price, each piece of the final product will be tested by a precise Three-dimensional detector to prove the qualify of dimensions.

Dimension inspection picture:

3. Custom anvil or anvil insert.

As one of the professional anvil manufacturers, we have advantages:

1. Good stable carbide quality. We use the top quality raw material and professional production technology in advanced production line base on mature formula to produce the stable good quality carbide anvil and inserts.The years experience in this industry and good market feedback also proved our profession.

2. Strict inspection processes to prove the quality.

1). Scanning electron microscope, to inspect the micro structure of the anvil material, to detect the material by random sample of small piece of anvil.

2). Each piece of carbide anvil needs to pass the detecting of Ultrasonic flaw detector, to make sure all anvils has a uniform inside structure without any internal crack, sand hole, or impurity.

3). Tens Mpa or tens pa pressure will be try pressed on the carbide anvil simulating to the real application to prove the press bearing capability before mass order for each new customer.

4). Strict demention inspection.

One 6 face anvil is 6 to 7 kgs, one static press need 6 pieces of anvils, take the HUANHE WHIRLWIND as example, the tungsten carbide anvil used to produce 10,000carats of diamonds is about 1kg, however the industry average comsumes is 2 to 3 kg, and the consumption level of small enterprises is even higher, hence the stability of quality of tungsten anvil is the key point for a anvil manufacturer to stand in the market for a long time and gain continual orders, work with us, you can see that we are worth long time cooperation.

Advanced machines make the large size range production to be possible:

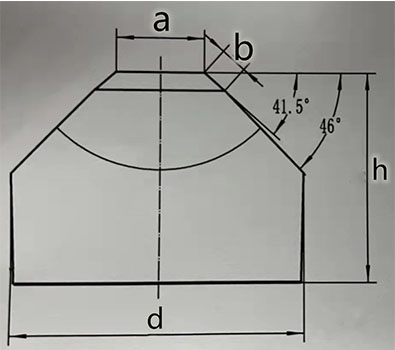

Diameter Range: 80mm to 300 mm, can be custom size in between, please contact us with detailed requirement.

Some size examples:

Anvil description | d(mm) | a*b(mm) | h(mm) |

Φ81 | Φ81 | 27*27 | 65 |

Φ85 | Φ85 | 31*31 | 64.5 |

Φ90 | Φ90 | 30*20 | 70 |

Φ105 | Φ105 | 36*36 | 76 |

Φ110 | Φ110 | 36*36 | 80 |

Φ115 | Φ115 | 38*38 | 83 |

Φ122 | Φ122 | 48*48 | 87 |

Φ127 | Φ127 | 44*44 | 94 |

Φ128 | Φ128 | 41.5*41.5 | 95 |

Φ130 | Φ130 | 48*48 | 95 |

Φ136 | Φ136 | 51*51 | 98 |

Φ142 | Φ142 | 55*55 | 100 |

Φ148 | Φ148 | 54*54 | 103 |

Φ160 | Φ160 | 62*62 | 115 |

Φ175 | Φ175 | 63*63 | 128 |

Φ199 | Φ199 | 76*76 | 142 |

Φ240 | Φ240 | 92*92 | 172 |

Φ260 | Φ260 | 92*92 | 190 |