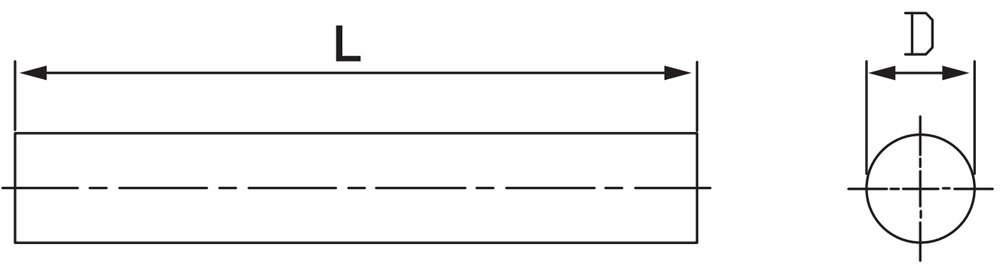

Betalent carbide keeps large quantity stock of standard carbide rods as-sintered in 310mm or 330mm length, which diameter starts from 4mm to 20mm. And because few customers need to use solid carbide bars of which diameter smaller than 4mm and larger than 20mm, they are not included in Betalent carbide’s regular stock, they are produced order by order. As far as production capability concerned, diameter lower limit is 0.5mm, the upper limit is 50mm, and length limit upper 1200mm, no strict lower limit.

Betalent carbide can produce 20tons carbide rods per month.

Solid carbide quality ensure system: 1, Raw material: Betalent uses the top-level quality tungsten carbide powder of the world from GESAC. 2, Strict production process control and good machines. 3, Strict quality control process, precise and comprehensive inspection equipment including carbon sulfur analyzer, TRS tester, Metallographic microscope(Check microstructure), coercive force tester, cobalt magnetic tester, Rockwell hardness tester, Vickers hardness tester, drop test device.

Betalent solid carbide rod target market: middle to top-level market.

Solid carbide rod is the most general shape of tungsten carbide blank material for cutting tools. And for cutting tools application, tungsten carbide grain size ranges from sub-micron to nano, because small tungsten carbide size enables the cutting tool with a very sharp cutting edge and very good wear resistance, Betalent carbide grades most hot selling for solid carbides are BT45, BT50, BT55, BT60, if there is any special application, all Betalent carbide grades including fine to coarse grain size tungsten carbide grade can be applied to solid carbide rod accordingly.

Betalent carbide keeps large quantity stock of standard carbide rods as-sintered in 310mm or 330mm length, which diameter starts from 4mm to 20mm. And because few customers need to use solid carbide bars of which diameter smaller than 4mm and larger than 20mm, they are not included in Betalent carbide’s regular stock, they are produced order by order. As far as production capability concerned, diameter lower limit is 0.5mm, the upper limit is 50mm, and length limit upper 1200mm, no strict lower limit.

Solid carbide production capability:

Betalent carbide can produce 20tons carbide rods per month.

Raw material: Betalent uses the top-level quality tungsten carbide powder of the world from GESAC.

Strict production process control and good machines.

Strict quality control process, precise and comprehensive inspection equipment including carbon sulfur analyzer, TRS tester, Metallographic microscope(Check microstructure), coercive force tester, cobalt magnetic tester, Rockwell hardness tester, Vickers hardness tester, drop test device.

Betalent solid carbide rod target market: middle to top-level market.

| D (mm) | Tolerance (mm) | D h6 ground (mm) | D(mm) | Tolerance (mm) | D h6 ground (mm) | Length mm Tol:+1/+4mm |

| 3.0 | +0.2/+0.4 | 3.0 | 17.0 | +0.3/+0.8 | 17.0 | |

| 4.0 | +0.2/+0.4 | 4.0 | 18.0 | +0.3/+0.8 | 18.0 | 310 / 330 |

| 5.0 | +0.2/+0.4 | 5.0 | 19.0 | +0.3/+0.8 | 19.0 | 310 / 330 |

| 6.0 | +0.2/+0.4 | 6.0 | 20.0 | +0.3/+0.8 | 20.0 | 310 / 330 |

| 7.0 | +0.3/+0.5 | 7.0 | 21.0 | +0.3/+0.8 | 21.0 | 310 / 330 |

| 8.0 | +0.3/+0.5 | 8.0 | 22.0 | +0.3/+0.8 | 22.0 | 310 / 330 |

| 9.0 | +0.3/+0.5 | 9.0 | 23.0 | +0.3/+0.8 | 23.0 | 310 / 330 |

| 10.0 | +0.3/+0.6 | 10.0 | 24.0 | +0.3/+0.8 | 24.0 | 310 / 330 |

| 11.0 | +0.3/+0.6 | 11.0 | 25.0 | +0.3/+0.8 | 25.0 | 310 / 330 |

| 12.0 | +0.3/+0.6 | 12.0 | 26.0 | +0.3/+0.8 | 26.0 | 310 / 330 |

| 12.5 | +0.3/+0.6 | 12.5 | 27.0 | +0.3/+0.8 | 27.0 | 310 / 330 |

| 13.0 | +0.3/+0.6 | 13.0 | 28.0 | +0.3/+0.8 | 28.0 | 310 / 330 |

| 14.0 | +0.3/+0.7 | 14.0 | 29.0 | +0.3/+0.8 | 29.0 | 310 / 330 |

| 15.0 | +0.3/+0.7 | 15.0 | 30.0 | +0.3/+0.8 | 30.0 | 310 / 330 |

| 16.0 | +0.3/+0.7 | 16.0 | 31.0 | +0.3/+0.8 | 31.0 | 310 / 330 |

Remark:

1. Cut-to-length carbide rod can be customized.

2. All size can be h6 ground.

3. Size beyond listed above please inquire sales person for MOQ and price.