Carbide preform is a kind of carbide rod blank in a special shape which is near the final cutting tool shape, customer can customize the preform. The reason for a preform exist is that the tungsten carbide is very hard after sintering, to do machining on a sintered tungsten carbide blank is very difficult, usually by grinding or slow wire cutting EDM, which are very slow and expensive. However, before sintering, the tungsten density is low, easy to be cut, chamfered, grooved, or trimmed to different shapes, then it is sintered to be a preform with a shape close to final cutter shape, which saves lots of after-sintering machining time, cost and labor.

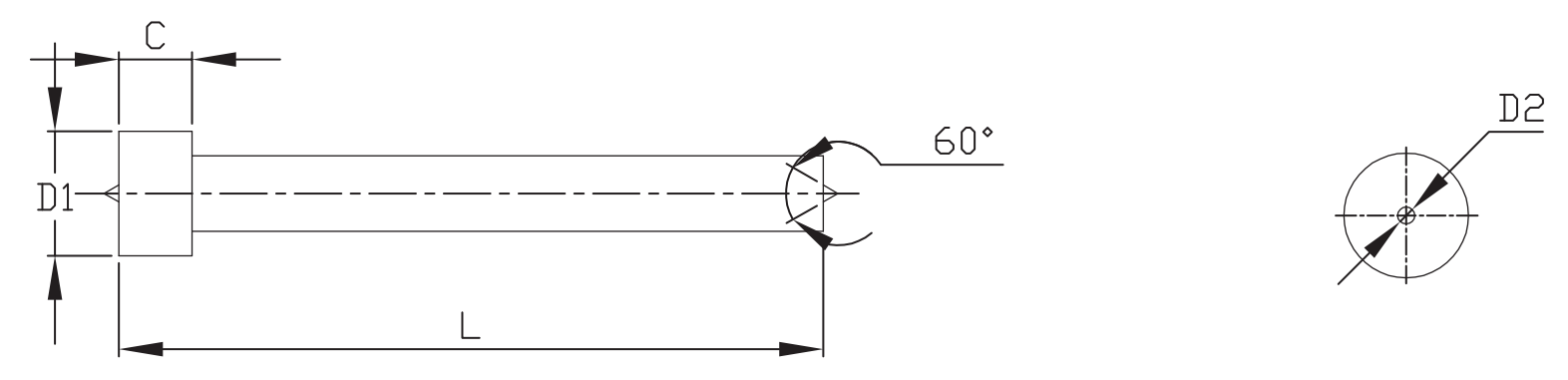

T shape preform is a typical preform shape, which has a very big blade head end and small shank end, one or more steps on the outer diameter of a carbide rod.

Carbide preforms are customized base on customer’s drawing, sample, or final cutter shape. Please contact the professional salesperson to get quotation case by case.

| ΦD1 | L | C | ΦD2 |

| 17 | 104 | 4 | 10.3 |

| 17 | 106 | 6 | 10.3 |

| 17 | 108 | 8 | 10.3 |

| 17 | 110 | 10 | 10.3 |

| 21 | 104 | 4 | 10.3 |

| 21 | 106 | 6 | 10.3 |

| 21 | 108 | 8 | 10.3 |

| 21 | 110 | 10 | 10.3 |

| 27 | 104 | 4 | 12.3 |

| 27 | 106 | 6 | 12.3 |

| 27 | 108 | 8 | 12.3 |

| 27 | 110 | 10 | 12.3 |

| 33 | 104 | 4 | 16.3 |

| 33 | 106 | 6 | 16.3 |

| 33 | 108 | 8 | 16.3 |

| 33 | 110 | 10 | 16.3 |

| 33 | 158 | 8 | 16.3 |

| 33 | 160 | 10 | 16.3 |

| 37 | 104 | 4 | 16.3 |

| 37 | 106 | 6 | 16.3 |

| 37 | 108 | 8 | 16.3 |

| 37 | 110 | 10 | 16.3 |

| 37 | 154 | 4 | 16.3 |

| 37 | 156 | 6 | 16.3 |

| 37 | 158 | 8 | 16.3 |

| 37 | 160 | 10 | 16.3 |

| 41.3 | 104 | 4 | 16.3 |

| 41.3 | 106 | 6 | 16.3 |

| 41.3 | 108 | 8 | 16.3 |

| 41.3 | 110 | 10 | 16.3 |

| 41.3 | 154 | 4 | 16.3 |

| 41.3 | 156 | 6 | 16.3 |