In some cases, such as drilling, the external pouring coolant fluid can not enter the hole to cool the cutting edge of the drill effectively, especially when the hole depth is more than 3 times of drill bit cutting diameter, the internal cooling works, at the same time, the high-pressure cutting fluid with pressure through the internal cooling hole is also conducive to chip removal. Therefore, compared with external cooling, the application of internal cooling cutting tools can improve the cutting parameters, improve the production efficiency, and fit more complicated cutting situations.

※Grade options

| Grade | Grain size | Cobalt content | Density | Hardness | TRS |

| um | g/cm3 | HRA | N/mm2 | ||

| BL610 | 0.55 | 10% | 14.4 | 92 | 4300 |

| BL510 | 0.5 | 10% | 14.4 | 92.4 | 4300 |

※Length limit:330mm,cut to length available\

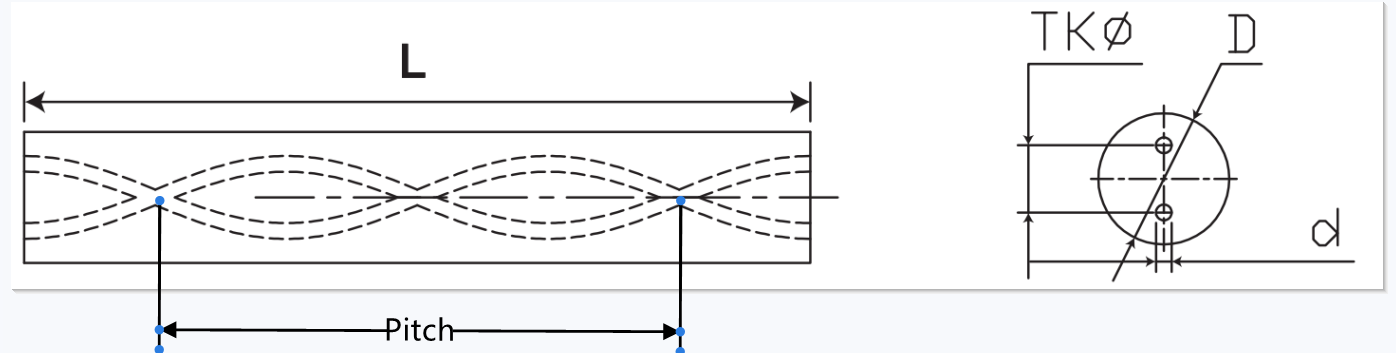

Standard Specification:

| d (mm) | Tol.(mm) | TK (mm) | Tol.(mm) | Pitch | ||

| 3.5 | 0.40 | ±0.1 | 1.60 | ±0.15 | 15.7-17.0 | |

| 4.5 | 0.60 | ±0.1 | 2.10 | ±0.15 | 20.9-22.7 | |

| 5.5 | 0.70 | ±0.1 | 2.40 | ±0.15 | 26.2-28.4 | |

| 6.5 | 0.70 | ±0.15 | 2.40 | ±0.15 | 31.4-34.0 | |

| 7.5 | 1.00 | ±0.15 | 3.50 | ±0.15 | 36.6-39.7 | |

| 8.5 | 1.00 | ±0.15 | 3.80 | ±0.15 | 41.9-45.4 | |

| 9.5 | 1.40 | ±0.15 | 4.50 | ±0.3 | 47.1-51.0 | |

| 10.6 | 1.40 | ±0.15 | 4.50 | ±0.3 | 52.3-56.7 | |

| 11.6 | 1.40 | ±0.15 | 4.90 | ±0.4 | 57.5-62.4 | |

| 12.6 | 1.40 | ±0.15 | 5.85 | ±0.4 | 62.8-68.1 | |

| 13.6 | 1.75 | ±0.2 | 6.10 | ±0.4 | 68.0-73.7 | |

| 14.6 | 1.75 | ±0.2 | 6.70 | ±0.4 | 73.2-79.4 | |

| 15.7 | 1.75 | ±0.2 | 7.30 | ±0.4 | 78.5-85.1 | |

| 16.7 | 1.75 | ±0.2 | 7.90 | ±0.4 | 83.7-90.7 | |

| 17.75 | 1.75 | ±0.2 | 8.50 | ±0.4 | 88.9-96.3 | |

| 18.75 | 2.00 | ±0.25 | 9.15 | ±0.4 | 94.1-102.0 | |

| 19.75 | 2.00 | ±0.25 | 9.70 | ±0.4 | 99.3-107.7 | |

| 20.75 | 2.00 | ±0.25 | 9.90 | ±0.5 | 104.6-113.4 | |

| 22.75 | 2.00 | ±0.25 | 11.10 | ±0.5 | 114.96-124.62 | |

| 25.75 | 2.00 | ±0.25 | 12.80 | ±0.5 | 130.64-141.61 | |

Right spiral angle 30° three holes

| Outer D (mm) | OD Tol. (mm) | TK (mm) | Distence Tol. (mm) | Inner Dia. (mm) | ID Tol. (mm) | Pitch (mm) | Pitch Tol. (mm) |

| 6 | +0.6/+1.0 | 2.75 | -0.4 | 0.7 | ±0.10 | 32.7 | ±0.7 |

| 8 | +0.7/+1.4 | 3 | -0.4 | 1 | ±0.15 | 43.53 | ±0.9 |

| 10 | +0.7/+1.4 | 5 | -0.6 | 1.4 | ±0.15 | 54.41 | ±1.2 |

| 12 | +0.7/+1.4 | 6 | -0.6 | 1.4 | ±0.15 | 65.3 | ±1.3 |

| 14 | +0.7/+1.5 | 7 | -0.8 | 1.75 | ±0.20 | 76.18 | ±1.5 |

| 16 | +0.7/+1.6 | 8 | -0.8 | 1.75 | ±0.20 | 87.06 | ±1.8 |

| 18 | +0.7/+1.7 | 9.55 | -0.8 | 2 | ±0.25 | 97.95 | ±2.0 |

| 20 | +0.7/+1.7 | 10 | -1 | 2 | ±0.25 | 108.83 | ±2.2 |

Remark: If size you required is beyond above listed, please contact sales person for customization, which requires MOQ and mould fee.