Screw die is a very important application for tungsten carbide material. With years experience in this area, Betalent developed a special series popular carbide grades for screw die.

Screw Die Carbide Grade

Grade | Co% | Grain Size(um) | Density (g/cm) | Hardness(HRA) | TRS N/mm2 | Impact force (Kgf-m/cm²) | Application |

BH35 | 23 | 2-6 | 13.2 | 83.8 | 2550 | 0.92 | Hot heading or big size screw die |

BA90 | 24 | 2.0-6.0 | 13.22 | 82.8 | 2700 | 0.9 | Big head screw die |

BS6 | 18 | 3.0-6.0 | 13.7 | 85.8 | 2740 | 0.78 | Stainless steel screw die |

BS7 | 20 | 2.0-6.0 | 13.4 | 85 | 2640 | 0.8 | |

BT07 | 16 | 1.0 | 13.95 | 88.5 | 3600 | 0.8 | Small diameter bolt die,lock core die |

BA65 | 18 | 2.0-6.0 | 13.73 | 85 | 3000 | 0.8 |

Screw die carbide grade selection tips:

1, What’s the screw material you are going to produce with this die. In most situation, above grades can meet the needs, and we are continually developing new grades for some new series application.

2, Which station of the machine the screw dies will apply in, if you are using multi station screw machines.

3, What’s the key problem with current carbide grade, if you want to improve.

4, What’s the carbide grade and from which company, if you want to switch to a new supplier, and try some samples before placing mass order, to make sure what you get from new supplier is qualified and can satisfy your need.

About screw die size we can make

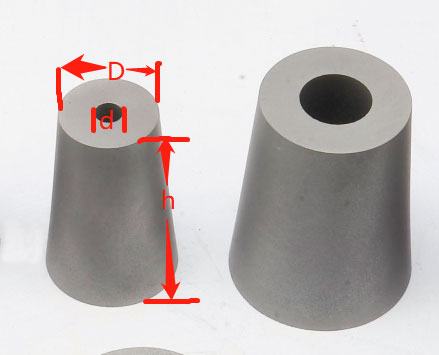

Common popular size for screw die is the D within 50mm, d within 50mm, and height within 160mm. Figure as below:

D(mm) | d(mm) | h(mm) | |

Size range | 3-50 | 1-50 | 2-160 |

For custom size beyond this range, please contact our sales staff for further checking.

Shape of screw die, straight cylinder with hole is most common. Straight hole with step outer diameter is also available, step hole is also possible, and the grinding service base on blank can be offered as per your drawing.

Additional information

Screw production steps:

1, Choose 5 to 19mm wire, rough drawing, annealing and pickling phosphating

2. Fine drawing to required size.

3, Forming, which is divided into three steps: cold heading, clamping tail, making thread. (The carbide screw die we offered is applied in cold heading step, and we also offer drill point die for clamping tail step)

4, Heat treatment, which is divided into cleaning, high temperature carburizing, quenching, cleaning quenching oil, low temperature tempering, electroplating