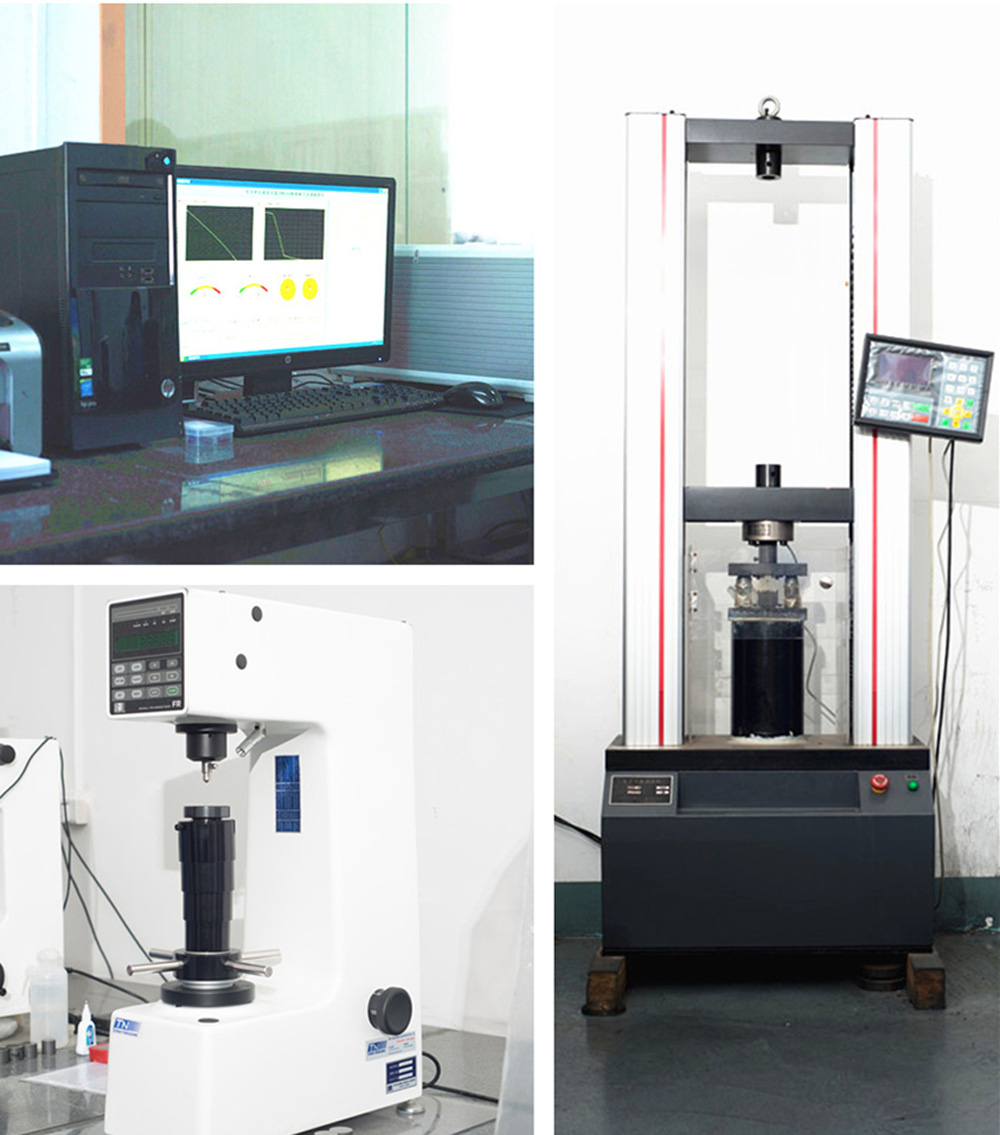

1. Advanced inspection instruments

Carbon sulfur analyzer, TRS tester, Metallographic microscope, Coercive force tester, Cobalt magnetic tester, Rockwell hardometer, Vickers hardometer, Drop test device, micrometer, roundness tester, ultrasonic scanner

2. Inspection process

Raw material inspection: Use a carbon-sulfur analyzer to make sure the chemical composition of tungsten carbide powder is qualified.

Material inspection by instrument after sintering: Test TRS, microstructure, cobalt content, hardness of the material, for carbide rod add dropping testing to make sure there is no middle inside material flaw, and for carbide die blank, add an ultrasonic scanner to avoid sand hole inside the blank.

Material inspection by manual after sintering: Check by skilled workers by eye the material flaw, including carburization and decarbonization, sand hole in the surface, a small crack

Size inspection after sintering: Inspect size by Micrometer, for carbide rods, add roundness testing.

3. Production process control

Strictly quality control in each production process, qualified product standards are made for each process, those unqualified semi-finished product will not flow to next process.

4. Purchase good quality raw material

GESAC tungsten carbide powder is used as raw material,to ensure the stable and high quality level of raw material.

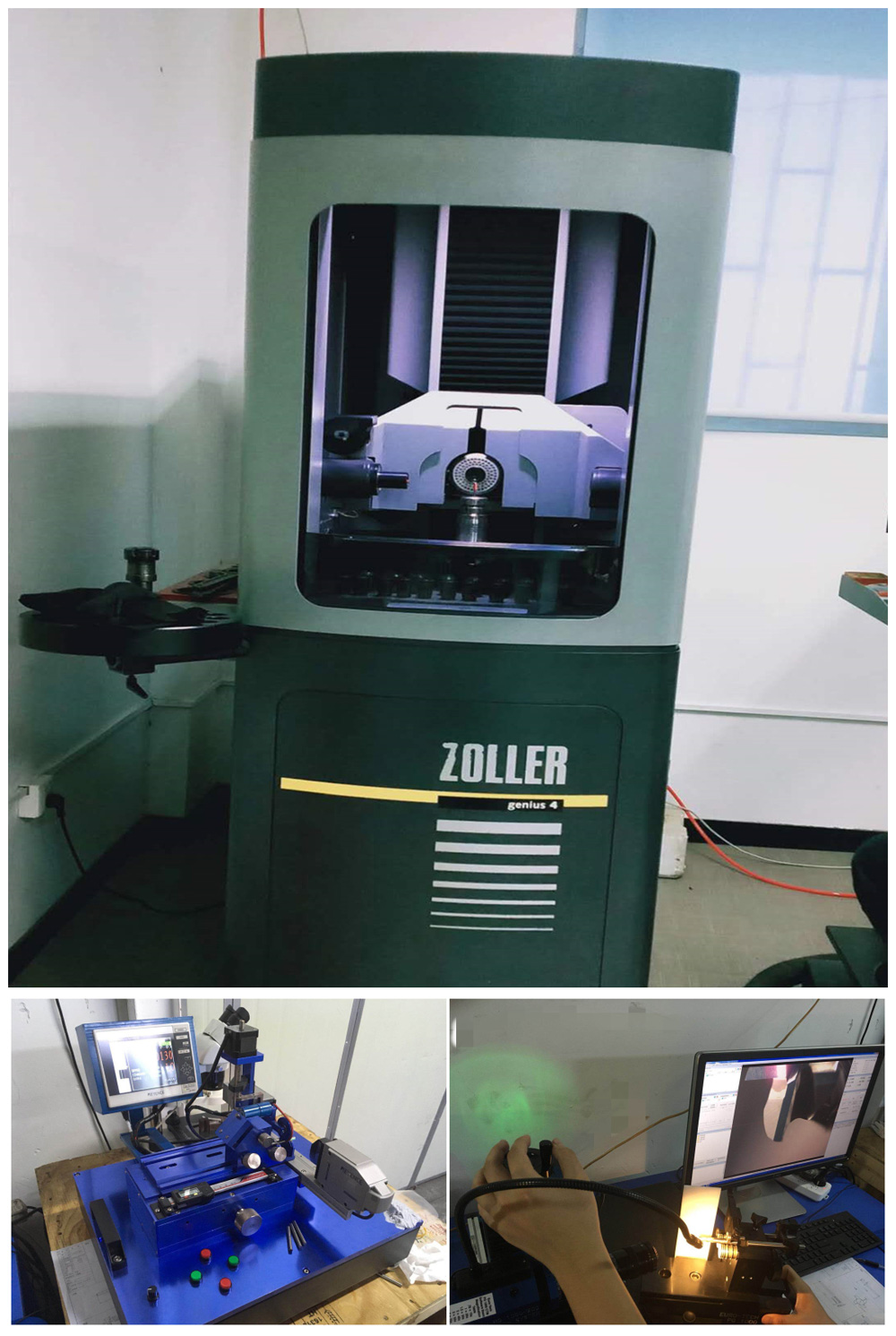

1. Advanced inspection instruments

Zoller, microscope,PG-1000

2. Expect inspection team

100% inspection for each irregular customized cutting tools, and random check to standard cutting tools, if found any flaw, 100% inspect the batch.

3. Use above qualified raw material

Use above very good quality cemented carbide materials manufactured by Betalent Carbide.