BT45, for milling materials of which hardness range from HRC45degree to HRC48degree, workpiece categories P, K, and softer stainless steel under M group in ISO classification.

BT50, for HRC50 to HRC53degree, mainly for M, N, and K group workpiece.

BT55, for HRC55 to HRC58degree, for S, M, and K workpiece.

BT60, for HRC 60 to 65degree, for milling quenched materials (HRC65 about), hardwood, and finish milling of SUS 316L stainless steel, most workpiece under ISO category H.

BT45, for milling materials of which hardness range from HRC45degree to HRC48degree, workpiece categories P, K, and softer stainless steel under M group in ISO classification.

BT50, for HRC50 to HRC53degree, mainly for M, N, and K group workpiece.

BT55, for HRC55 to HRC58degree, for S, M, and K workpiece.

BT60, for HRC 60 to 65degree, for milling quenched materials (HRC65 about), hardwood, and finish milling of SUS 316L stainless steel, most workpiece under ISO category H.

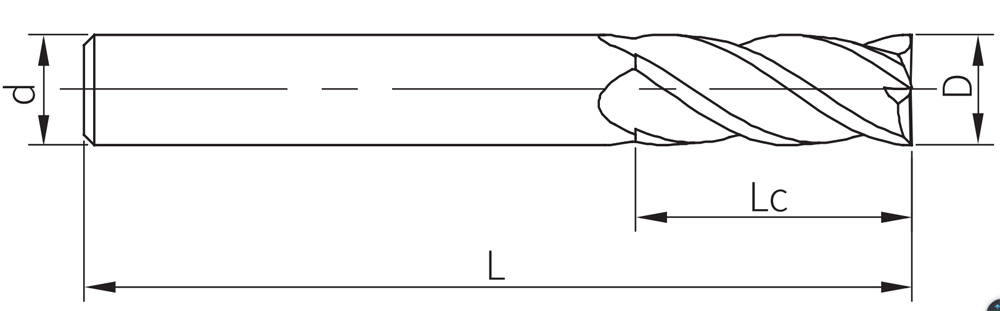

D Cutting Dia.(mm) | d Shank Dia.(mm) | Lc Cutting length(mm) | L Overall length(mm) |

| 6 | 6 | 18 | 50 |

| 6 | 6 | 24 | 75 |

| 6 | 6 | 30 | 100 |

| 8 | 8 | 20 | 75 |

| 8 | 8 | 35 | 100 |

| 10 | 10 | 25 | 75 |

| 10 | 10 | 40 | 100 |

| 12 | 12 | 30 | 75 |

| 12 | 12 | 45 | 100 |

| 16 | 16 | 40 | 100 |

| 16 | 16 | 70 | 150 |