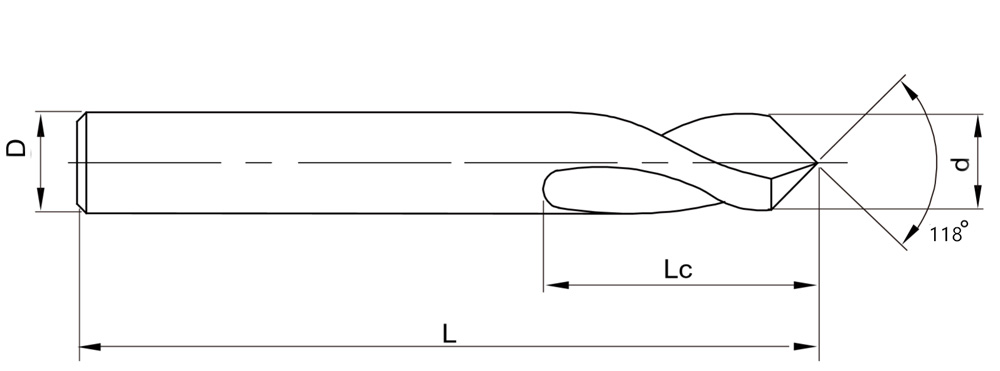

Betalent twist drill bits are manufactured by Walter 5-axil grinding machine base on submicron grain size tungsten carbide rods, which enable the edge very sharp and a high wear-resistance. In terms of design, the 118 ° double back angle design ensures the accurate positioning of the bit at the start of the drilling, which convenient the drilling, and the U-shaped groove chip removal design ensures smooth chip removal. Lots of standard fixed shank drill bits (left-hand and right-hand) and straight shank drills (left-hand and right-hand) are stored in Betalent carbide warehouse, ready to ship, irregular size or special design carbide drill bits can be customized.

Betalent twist drill bits are manufactured by Walter 5-axil grinding machine base on submicron grain size tungsten carbide rods, which enable the edge very sharp and a high wear-resistance. In terms of design, the 118 ° double back angle design ensures the accurate positioning of the bit at the start of the drilling, which convenient the drilling, and the U-shaped groove chip removal design ensures smooth chip removal. Lots of standard fixed shank drill bits (left-hand and right-hand) and straight shank drills (left-hand and right-hand) are stored in Betalent carbide warehouse, ready to ship, irregular size or special design carbide drill bits can be customized.

| d=D Cutting dia.(mm) | Lc Cutting length(mm) | L Overall length (mm) |

| 0.80-1.00 | 12 | 50 |

| 1.05-1.50 | 14 | 50 |

| 1.55-5.00 | 18 | 50 |

| 2.05-2.50 | 20 | 50 |

| 2.55-3.00 | 25 | 50 |

| 3.05-4.00 | 25 | 50 |

| 4.05-4.50 | 25 | 50 |

| 4.55-5.00 | 25 | 50 |

| 5.05-6.00 | 25 | 50 |

| 6.05-6.50 | 30 | 60 |

| 6.55-7.00 | 30 | 60 |

| 7.05-7.50 | 40 | 75/80 |

| 7.55-8.00 | 40 | 75/80 |

| 8.05-8.50 | 40 | 75/80 |

| 8.55-9.00 | 40 | 75/80 |

| 9.05-9.50 | 40 | 75/80 |

| 9.55-10.00 | 40 | 75/80 |

| 10.05-10.50 | 45 | 100 |

| 10.55-11.00 | 45 | 100 |

| 11.05-11.50 | 50 | 100 |

| 11.55-12.00 | 50 | 100 |

Remark:

1. Tolerance of d is within 0.005mm.Standard size in stock, ready to ship.

2. Accept customize.

3. Tip angle 118°,d tolerance within 0.005mm

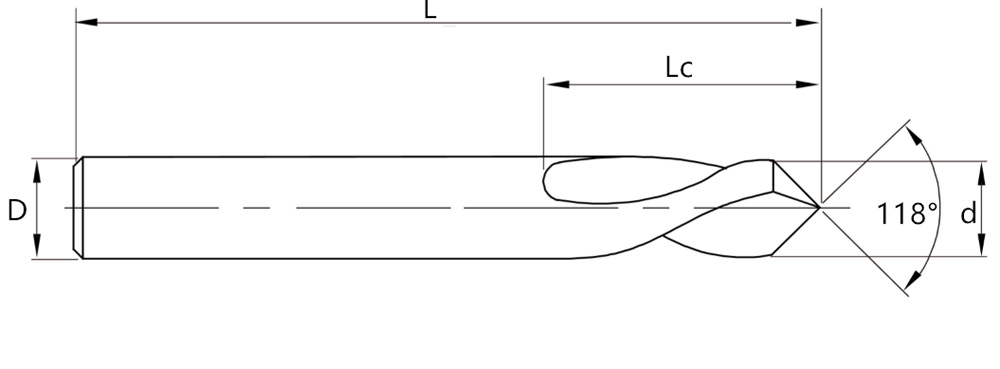

| d=D Cutting dia.(mm) | Lc Cutting length(mm) | L Overall length (mm) |

| 1.05-1.55 | 10 | 30 |

| 1.60-2.00 | 15 | 40 |

| 2.05-2.50 | 18 | 40 |

| 2.55-3.00 | 18 | 40 |

| 3.05-3.50 | 22 | 40 |

| 3.55-4.00 | 25 | 50 |

| 4.05-5.00 | 25 | 50 |

| 5.05-5.50 | 25 | 50 |

| 5.55-6.00 | 25 | 50 |

| 6.05-6.50 | 28 | 60 |

| 6.55-7.00 | 28 | 60 |

Remark:

1. Tolerance of d is within 0.005mm.Standard size in stock, ready to ship.

2. Accept customize.

3. Tip angle 118°,d tolerance within 0.005mm