Carbide Cutting Tool Manufacturing Process

Carbide End Mill and Drills: 1. Select qualified ground cut-to-length carbide rod. 2. Machine the end mill as per drawing in 5-axis WALTER or ROLLOMATIC grinding machines. 3. Inspect the geometry shape and the size of, flute. 4. Do proper coating to the flutes if necessary.5. Inspect the flutes with a Zoller tester. 6. Pack and ship as per order.

Carbide Inserts: 1. Make formula tungsten carbide powder by spray dry tower. 2. Press. Trim with CNC machine. Get the insert shape. 3. Sinter. Come out the hard insert blank. 4, Precision machining. Cutting, grinding, polishing. 5. Inspection. The inspection also should be done after each process to make sure only qualified products can be pass to the next process. 6. Pack and ship as per order.

Industry blades: 1. Select qualified carbide blank. 2. Precision machining. Cutting, grinding, polishing by CNC machines, EDM, centerless grinding machine, OD grinder, Wire cutting machines, etc. 3.Inspection. 4. Pack and ship as per order.

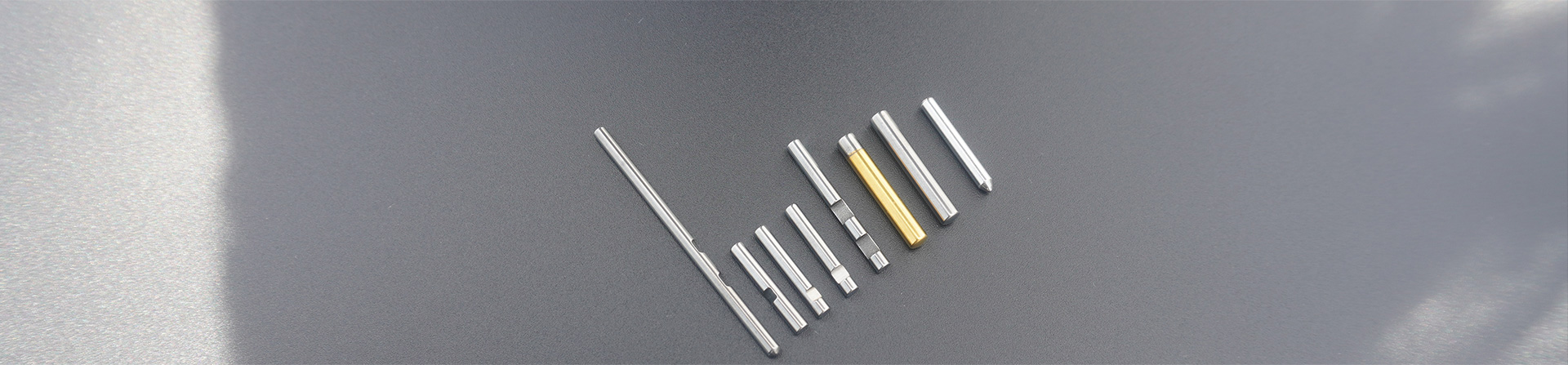

Types of Carbide Cutting Tools

Carbide Cutting Tools for Lathes

Common cutting tools for lathe production and manufacture of hardware products including end mills, drills, inserts, turning tool, special-shaped blades, and other accessories, such as round bar, embossing wheel, saw blade, knurled wheel, etc., different manufacturing process needs different cutting tools, Betalent carbide focus on making carbide end mills, carbide drills, carbide tips, carbide industrial blades, and customized irregular shape carbide cutting tools.

Carbide Cutters for metal

Hardness of most metals is below 65HRC, which is within the machining capability of various formulated cemented carbide. Carbide cutters for metals including carbide insert, carbide end mill, carbide drills, carbide taps, and carbide blades in various shapes. Contact Betalent carbide for professional information in these areas.

Carbide Cutters for woodturning tools

Woodturning is important for furniture manufacture. Traditional carbide cutters for woodturning tools including carbide drill bits, carbide end mills, carbide inserts for face milling cutter. Carbide grades BT45 to BT60 are applied in this machining area, and the different coating is applied for different hardness wood.

English

English  日本語

日本語  français

français  Deutsch

Deutsch  Español

Español  русский

русский  português

português  العربية

العربية  tiếng việt

tiếng việt